How Grasso ammonia compressor is highly reliable

When it comes to Grasso screw compressors, they are known for well-acceptability for several cooling and aircon era applications. And even its costing entirely depends on electricity performance, reliability, price performance, and sustainability.

Overall, it gives a perfect refrigeration potential towards a decrease in funding. The velocity boom presents customers with a full-size boom in potential. Because of the proportional correlation of compressor velocity, swept extent, and ensuing potential, 25 % greater potential can now be received using identical models. That returns a full-size improvement (reduction) of the relative rate as Kilowatts in line with the Euro. Alternatively, customers with a specific, constant potential requirement can enjoy the better speeds with the aid of letting them obtain the potential needs with smaller compressor devices which means much less funding and much fewer carrier costs. Moreover, Compressors at better speeds provide full-size financial savings potential in your Total Cost of Ownership, decreased footprint, and CO2 emissions.

Technical features

- Increased capacity. offering extra capacity, decreasing funding costs

- Extended velocity variety as much as 1,500 rpm

- Reduced footprint, the usage of smaller compressors at better velocity

- Environment-friendly, 0 GWP (Global Warming Potential) because of distinct use of the herbal refrigerant NH₃ (ammonia)

The packaging solution

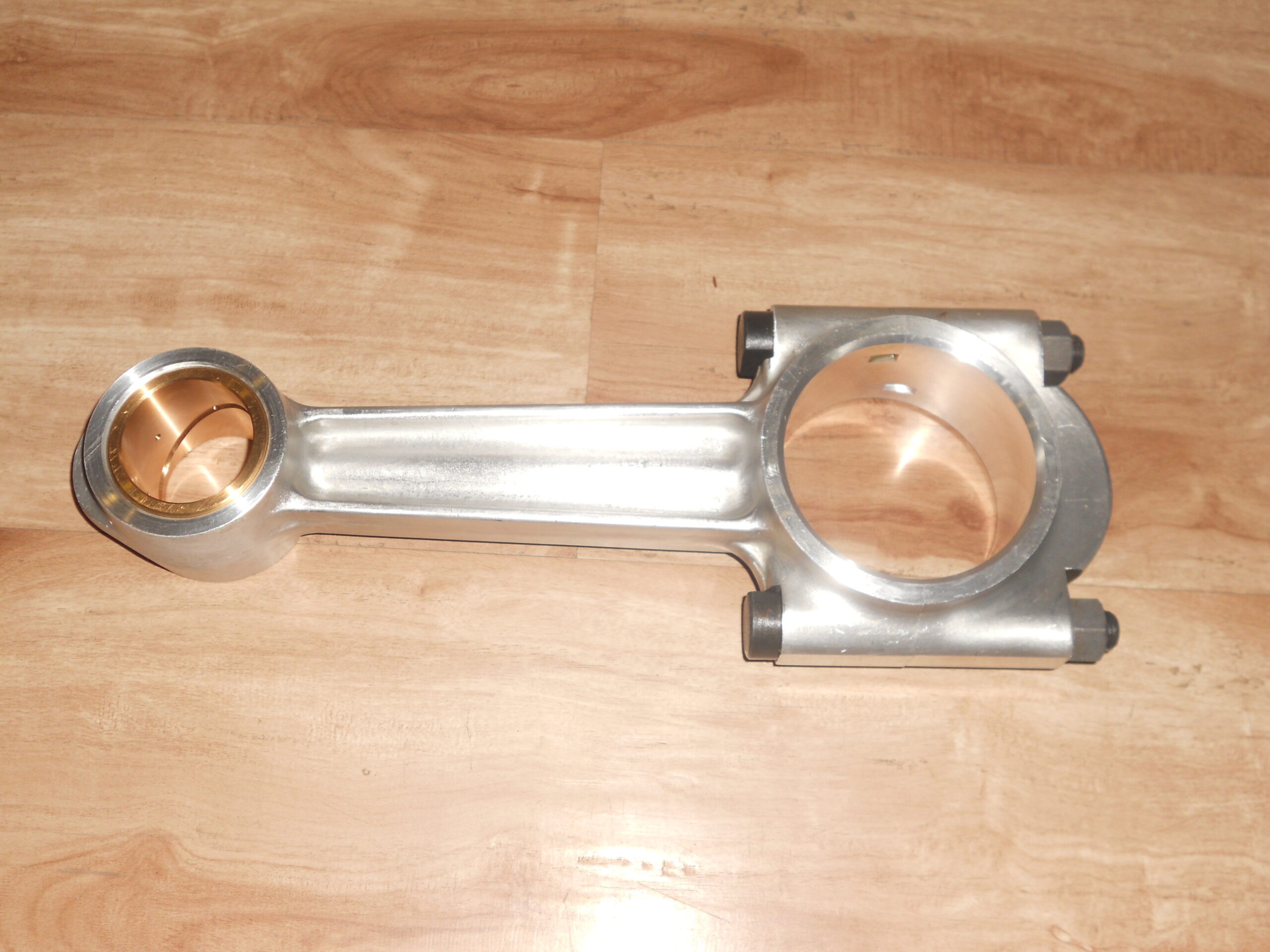

The GEA Grasso V collection programs may be divided into single and two-stage. The single-stage reciprocating compressor programs of the GEA Grasso V collection consist of 7 sizes in V-belt, in addition to direct pressure execution in an ability that varies from one hundred fifty to 900 kW. The -degree reciprocating compressor programs consist of 7 sizes in V-belt, in addition to direct pressure execution in an ability variety from 50 to three hundred kW. For the -degree reciprocating compressor programs, excessive green, and compact inter-degree coolers are available.

Special Features

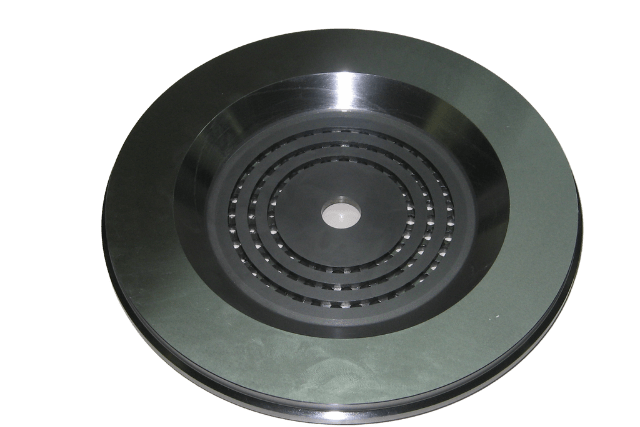

The latest designed compressor with a computerised indication of the specified carrier periods by way of the progressive GEA Maintenance Monitor is properly obtained with the help of using the marketplace as “the selection for the future”. Due to the acute low oil carryover, the oil separator is regularly overlooked to secure fees and engine room space.

Characteristics

Flexible and prolonged preservation periods

Lowest feasible strolling cost

Extreme low oil carry-over

For inflexible or spring-damper mounting

Latest V belt technology

SHA/SG with condensing units

With the modern-day collection of units, GEA gives you a complete variety from 6, four to 146, nine m³/displacement. The said overall performance information is primarily based totally on 20°C (25°C) suction gas temperature with liquid subcooling at 60 Hz.

GEA Grasso 5HP series

Reciprocating compressors: The fine preference to lessen your electricity expenses Freezing applications. The extraordinarily low extent with the drift about the cooling potential makes this collection a large performer.

Conclusion

With close to 35 years of experience in designing and manufacturing after market zero-defect industrial refrigeration compressor parts and reconditioned compressors, Jyoti Engineering Combine is a global leader in providing energy-efficient, customer centric solutions that meet every unique compressor requirement. We assess the needs of our clients and help them choose the best product. We also provide repair & maintenance of refrigeration compressor.